The Extreme Duty Series from Cleereman sets the industry standard for heavy-duty linear positioning sawmill carriages in strength, durability, simplicity, and performance. The clean, robust design has been proven world-wide to be a highly dependable, low maintenance carriage producing accurate boards and cants. Extreme Duty carriages can be built in any size from a 36” to 54” or more.

Several options are available to meet your requirements for layout, production, log and cant turning, and maintenance.

Other Linear Positioning Carriages

- Horizontal or Tilt Frame – Meets customer needs, easily integrated into existing systems

- Two to five headblocks set at customer specified spacing – Meets customer needs for log lengths and mixes

- Standard frame is precision fabricated from massive, 1/2” wall, 8” x 8” and 6” x 8” tubing – Rigid, accurate, long-lasting

- Larger frames are available as options – Extreme duty carriages built to meet your specific needs

- Carriage axles are machined from a single 2 3/4” square alloy blank – makes carriage more rigid,and tracks perfectly for accurate lumber and cants

- 14” wheels equipped with Timken roller bearings are mounted on 64” centers – smooth, trouble-free, accurate operation.

- Heavy-duty fabricated 3/4” bunks utilize long lasting 3/4” alloy steel wear plates – can be replaced to extend overall carriage life

- Knees are precision fabricated from 1” solid steel bases and two 5/8” side plates and 3/4” face plates – longer lasting, more durable

- Knees attach to bunks with a wrap-around mount for stability – extremely accurate lumber, high durability, less maintenance

- Adjustable, replaceable synthetic wear strips on the top, bottom, and sides of knee mounts – maintains perfect fit, easy maintenance, long life

- 5” stroke on dogs in and out position.

- 1” thick T1 center-mounted alloy steel tong-dogs – Locks log firmly in place for sure positioning and cuts down to a 1” backing board.

- Setworks Ready – Use the standard included PTJ setworks, or integrate it with any other setworks or optimization programs.

- Premium quality components – Hold up in extreme sawmill environments for precise, trouble free operation.

- 30 HP hydraulic power unit with 5 gallon accumulator, low and high pressure filters – smooth performance and recovery, increased production, low maintenance.

- Engineered to be simple and efficient – Minimal training time, easy and comfortable to control.

- OSHA approved air lock-out assembly — Increased employee safety

- Easy to access grease fittings, oversized oil cups — Easy maintenance

- Two, three, four and five head block carriages available

- 36”, 42”, 48” and 54” openings available in this series carriage line

- Any head block spacing available to meet customer’s specific requirements

- Custom built frames to meet elevation challenges

- Custom tilted frames

- 5/8” Wall tube frames up to 12” tube

- Anti derailer

- Axles through the frame

- Custom axles centers to fit existing rail centers

- Custom wheel machining to match existing rail profile

- Extra wheel and axle assemblies

- Plastic wheels

- 16” wheels and 3” axles

- 1 ½” thick T1 Dogs

- 4” Bore dog cylinders

- Dual air pressure on dogs

- Cinch back cylinders

- Brownsville turners

- Side mount turners

- On board Chain turners

- 3 Position face plates

- Cant push offs

- Cam style push offs

- Double bit hammer dog

- Custom cable hook ups

- Dual cable equalizer systems

- Shot gun bracket

- Valve heaters

- Track and wheel cleaners

- Pressurized lube system for wheels and rail

- Automatic injection lube system for knees, wheels and rail

- Blow offs

- Nitride Process wear plates

- Chromed wear plates

- Features & Benefits

-

- Horizontal or Tilt Frame – Meets customer needs, easily integrated into existing systems

- Two to five headblocks set at customer specified spacing – Meets customer needs for log lengths and mixes

- Standard frame is precision fabricated from massive, 1/2” wall, 8” x 8” and 6” x 8” tubing – Rigid, accurate, long-lasting

- Larger frames are available as options – Extreme duty carriages built to meet your specific needs

- Carriage axles are machined from a single 2 3/4” square alloy blank – makes carriage more rigid,and tracks perfectly for accurate lumber and cants

- 14” wheels equipped with Timken roller bearings are mounted on 64” centers – smooth, trouble-free, accurate operation.

- Heavy-duty fabricated 3/4” bunks utilize long lasting 3/4” alloy steel wear plates – can be replaced to extend overall carriage life

- Knees are precision fabricated from 1” solid steel bases and two 5/8” side plates and 3/4” face plates – longer lasting, more durable

- Knees attach to bunks with a wrap-around mount for stability – extremely accurate lumber, high durability, less maintenance

- Adjustable, replaceable synthetic wear strips on the top, bottom, and sides of knee mounts – maintains perfect fit, easy maintenance, long life

- 5” stroke on dogs in and out position.

- 1” thick T1 center-mounted alloy steel tong-dogs – Locks log firmly in place for sure positioning and cuts down to a 1” backing board.

- Setworks Ready – Use the standard included PTJ setworks, or integrate it with any other setworks or optimization programs.

- Premium quality components – Hold up in extreme sawmill environments for precise, trouble free operation.

- 30 HP hydraulic power unit with 5 gallon accumulator, low and high pressure filters – smooth performance and recovery, increased production, low maintenance.

- Engineered to be simple and efficient – Minimal training time, easy and comfortable to control.

- OSHA approved air lock-out assembly — Increased employee safety

- Easy to access grease fittings, oversized oil cups — Easy maintenance

- Options

-

- Two, three, four and five head block carriages available

- 36”, 42”, 48” and 54” openings available in this series carriage line

- Any head block spacing available to meet customer’s specific requirements

- Custom built frames to meet elevation challenges

- Custom tilted frames

- 5/8” Wall tube frames up to 12” tube

- Anti derailer

- Axles through the frame

- Custom axles centers to fit existing rail centers

- Custom wheel machining to match existing rail profile

- Extra wheel and axle assemblies

- Plastic wheels

- 16” wheels and 3” axles

- 1 ½” thick T1 Dogs

- 4” Bore dog cylinders

- Dual air pressure on dogs

- Cinch back cylinders

- Brownsville turners

- Side mount turners

- On board Chain turners

- 3 Position face plates

- Cant push offs

- Cam style push offs

- Double bit hammer dog

- Custom cable hook ups

- Dual cable equalizer systems

- Shot gun bracket

- Valve heaters

- Track and wheel cleaners

- Pressurized lube system for wheels and rail

- Automatic injection lube system for knees, wheels and rail

- Blow offs

- Nitride Process wear plates

- Chromed wear plates

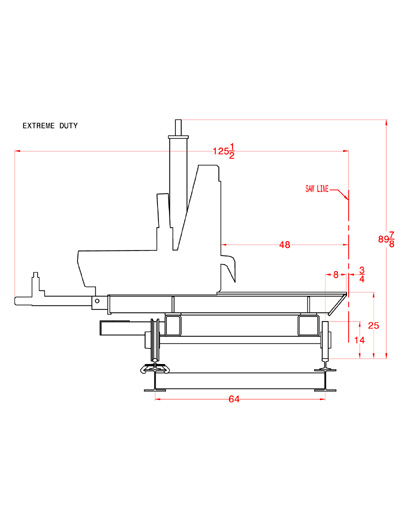

- Specifications & Dimensions